Cleanliness inspection

Release date:2025-06-03

What is cleanliness testing?

Cleanliness testing is a key means to quantify contaminants through standardized methods and ensure product reliability. The VDA 19.1 standard is an important guideline for technical cleanliness testing in the global automotive industry.

Why is it necessary to conduct cleanliness tests?

1. Enhance product reliability

Reduce problems such as engine wear, electronic component failure, hydraulic system blockage and oil circuit blockage caused by particle contamination

Enhance the long-term stability of electric vehicle batteries and electric drive systems

The cleanliness of components directly affects the reliability and durability of the product

2. Optimize the production process

Trace pollution sources (such as processing residues, assembly environments, etc.) through cleanliness data

Improve the cleaning process and reduce the defect rate

3. Meet the requirements of the original equipment manufacturer

German automakers such as Volkswagen, BMW and Mercedes-Benz all require their suppliers to comply with the VDA 19.1 standard

Enhance supply chain competitiveness through cleanliness reports

At which stage is the cleanliness test carried out?

Product design and development stage

Cleanliness Risk Analysis (DFMEA) in the Design Phase

evalsuate the impact of processing techniques on cleanliness

Cleanliness verification of prototype parts or samples of the same process

2. Process design and development stage

Identification of cleanliness control points in the process flow chart

Verification of the cleanliness of the trial production environment

Particle contamination assessment of tooling fixtures and packaging materials

3. The confirmation stage of products and processes

Comprehensive cleanliness verification of PPAP samples

4. Feedback evalsuation and corrective action stage

Continuous monitoring of cleanliness after mass production

Optimization and update of the cleanliness control plan

What are the requirements for personnel conducting cleanliness tests at the Who?

Cleanliness inspectors must participate in the relevant training of VDA19.1 and pass the examination to obtain the corresponding qualification certificate

2. Proficient in using relevant equipment and familiar with the testing process

What are the requirements for the Where detection site?

1. Cleanliness (ISO grade 8 or higher)

Constant temperature and humidity (20±2℃, 45% - 65% RH)

3. Prevention of Cross-contamination (Independent area/Clean bench)

4. Standard Operation

What are the core steps of How cleanliness testing?

1. Sample Collection

Extraction method: Select an appropriate method based on the type of components, such as:

Pressure flushing method: Suitable for washable metal parts (such as engine blocks)

Ultrasonic cleaning: Suitable for precision components (such as electronic components)

Vibration method: Suitable for large components that cannot be rinsed

Filter medium: Use filter membranes with specific pore sizes (such as 5μm, 10μm) to collect particles

2. Particle Analysis

Microscopic analysis: Manual or automatic microscopic measurement of particle size, shape and quantity

Automatic particle counting: Image analysis software is adopted to enhance detection efficiency

Material identification (optional) : Determine the source of particles (metal, fiber, plastic, etc.) through EDX (energy spectrum analysis)

3 Result evalsuation

Count the quantity based on the particle size (such as ≥50μm, ≥100μm, ≥200μm)

Compare the limit standards set by the customer for this part to determine whether the component is qualified

The cleanliness inspection of Zhengcun

Masamura is equipped with a complete set of cleanliness testing equipment, including automatic cleanliness particulate matter extraction equipment, Olympus cleanliness testing equipment and analytical balances, etc. Three people have passed the VDA19.1 cleanliness inspection training and obtained the certificate in terms of personnel.

Next, we will introduce the cleanliness detection by taking the product BAC1363 as an example.

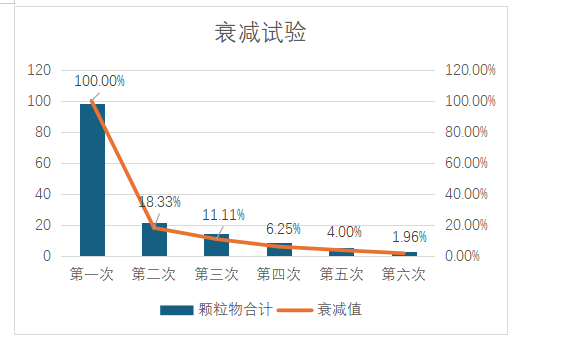

The first step is the attenuation test

The attenuation test is used to confirm the particulate matter extraction method for cleanliness. The appropriate particulate matter extraction method should be selected based on the shape of the product to carry out the attenuation test. This product, the Antenna Cover Plate, has a certain depth. Pressure cleaning should be selected to prevent particles from remaining inside during the extraction process. The surface area of the product is known through the 3D drawing, and the minimum number of products to be cleaned is calculated based on the standard. During the attenuation test, no pause or interruption is allowed. Set the cleaning duration and flow rate of the particulate matter extraction equipment for cleanliness. After continuous cleaning to obtain 6 filter membranes, dry them and use the detection equipment to detect the particulate matter quantity of each filter membrane. After statistics, perform the calculation.

The illustration shows the effective attenuation curve. If it decreases successively and the standard of being lower than 10% appears before the completion of 6 times, the particulate matter extraction method of this product can be determined. If the "10%" attenuation technical index does not occur or the distribution does not follow the law of successive decrease, the cleaning parameters should be adjusted and re-sampled to conduct the attenuation test.

The second step is to set the method

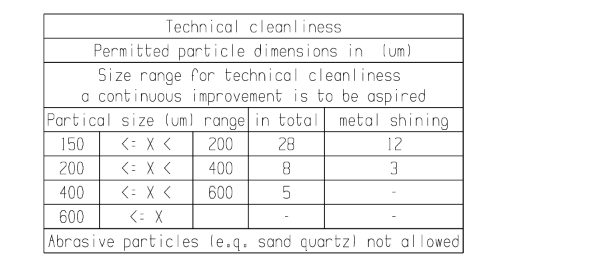

The size and number of particles to be detected are determined by reviewing the customer's cleanliness technical index documents, and the corresponding detection limits are set by adding new test methods on the cleanliness detection equipment.

The third step is to carry out the inspection

The samples must be taken from the packaged products of the complete process. The filter membranes are made by the cleanliness particulate matter extraction equipment, dried, and then the values of particulate matter of different sizes are obtained through the cleanliness detection equipment to screen out the effective particulate matter. Compare with the technical indicators of the customers. Obtain the test results.

The fourth step is result processing

If the results are found to be substandard during the development stage, relevant factors (such as adjusting the process route, etc.) should be considered. If substandard products are discovered in the later supply stage, the substandard batch products should be isolated and dealt with accordingly.

The above is a complete set of cleanliness detection procedures.

Last article:The continuous renovation of the factory

Next article:None